In the last two years, Senstech AG has invested heavily in future-oriented production technologies. This has reduced production costs and improved quality. We are now able to respond more flexibly and faster to special customer needs.

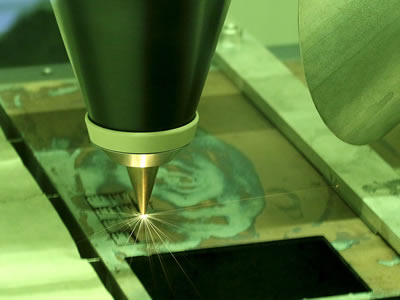

The new cutting laser enables ...

... fast and precise cutting of multi-sensor panels

Reliable control with the digital measurement projector

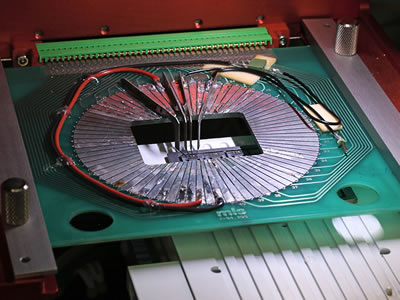

The new trim laser with integrated vision system

Via needles, the electrical signal is continuously measured

Verification with the digital microscope

Many Senstech sensors are cut out of high-quality spring plates with laser radiation.

Thanks to a newly-acquired Laser cutting machine with fiber laser we can now carry out the cutting processes internally. This results in significantly optimized processes and the ability to react even more flexibly to customer requirements.

In addition, the laser system can be used for tool manufacturing and for welding.

The quality of the cutting processes is assured using a likewise new and powerful digital measurement projector. Complex geometries can be verified and documented to 100% in the micrometer range.

The sputtering of thin layers is one of the main competences of Senstech AG. With these layers strain gauges are produced. New is Senstech AG with a Laser trimming system (picolaser) structure and trim these thin-film strain gauges (with laser ablation). This alternative to photolithographic processes is more efficient and flexible and greatly enhances Senstech's range of services.

Thanks to a high-resolution Digital Microscope the result of laser ablation in the sub-micron range can be checked well and corrected if necessary. The influence of humidity and temperature on the laser-structured strain gauges is tested during long-term measurements in a Climate Chamber .

During the trimming process, the strain gages are electrically contacted and with the help of a very fast and accurate measuring and control system, the properties can be trimmed to the desired values. Since the laser trimming system offers the possibility of individual labeling, complete traceability can be achieved.

The investments described above have reduced production costs and enhanced the product range of Senstech.