Our technology is increasingly used instead of foil strain gauges. Laser-welded thin-film sensors offer various advantages for load measurement on plant components, such as better temperature properties and increased long-term stability.

Measurements on Loaded Components

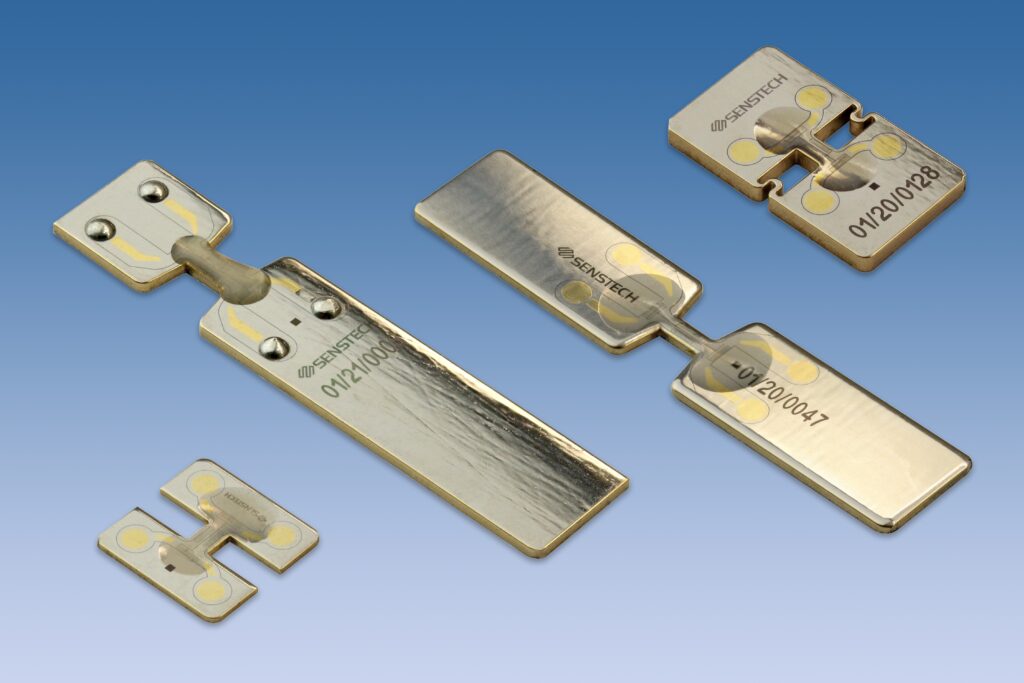

Strain gauges are used whenever the deformation or movement of a loaded component is to be measured. Thin-film-based sensors made of spring steel are a robust alternative to the common foil strain gauges attached with glue. These sensors are Laser welded to the substrate and achieve a particularly high sensitivity, since the deformation is concentrated on a weakened central zone of about 1×1 mm, on which the strain gauge elements are placed. This allows for deformations in the micrometer range to be measured.

Suitable for Industrial Use

Since a Wheatstone full bridge can be placed on a very small surface, which is thermally coupled to the underlying metal part, the measured signal is insensitive to temperature fluctuations. In contrast to glued-on sensors, creeping layers, which can impair long-term stability, are avoided. The welded-on sensors thus represent a measurement solution suitable for industrial use, not only for individual measurements, but also for permanent monitoring applications. Wear effects can be made visible over months or years.

Versatile Applications

Accordingly, such sensors are used e.g. in metal processing, where they monitor the load on tools, or in the automotive industry as part of a load measurement system. The measuring arrangement and the dimensions of the sensors can be adapted to the respective application from as little as approx. 100 pieces. Shear forces or multi-dimensional forces can also be measured. The smallest specimens are only 5×5 mm in size. One disadvantage is the additional Laser welding step; however, this is offered as a service by Senstech.