Senstech AG is launching two new products at this year's SENSOR+TEST in Nuremberg: the compact KB-011-1600 force sensor bracket and the SA-011-1500 mini signal amplifier.

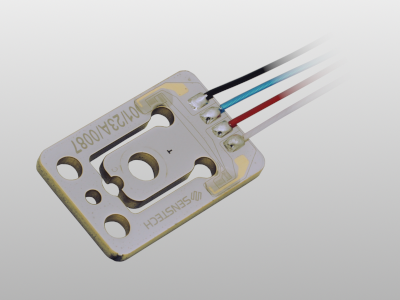

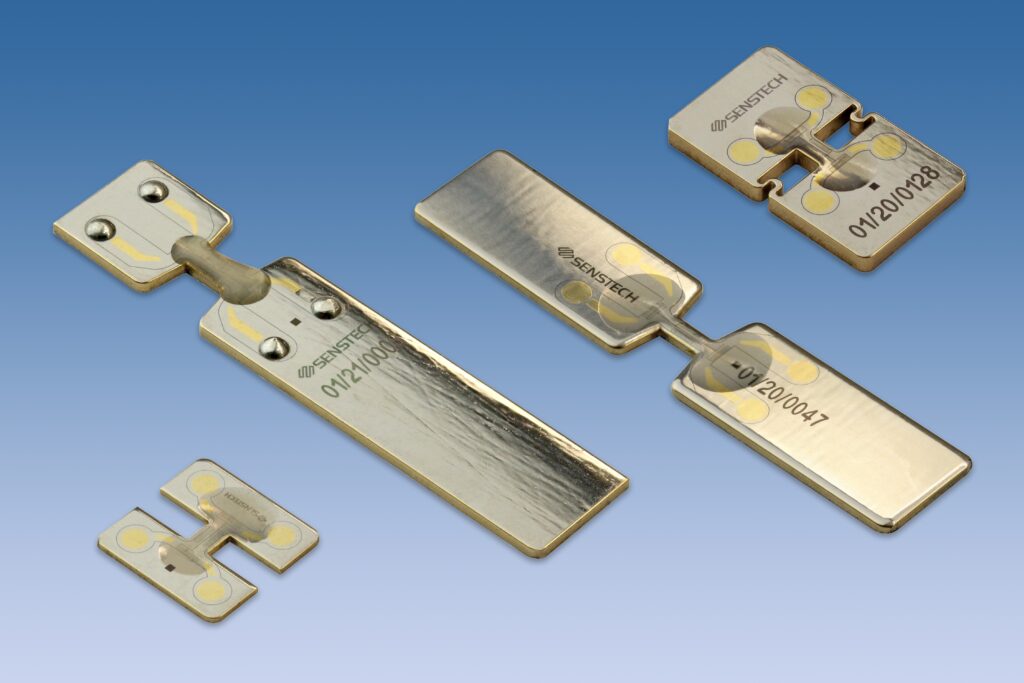

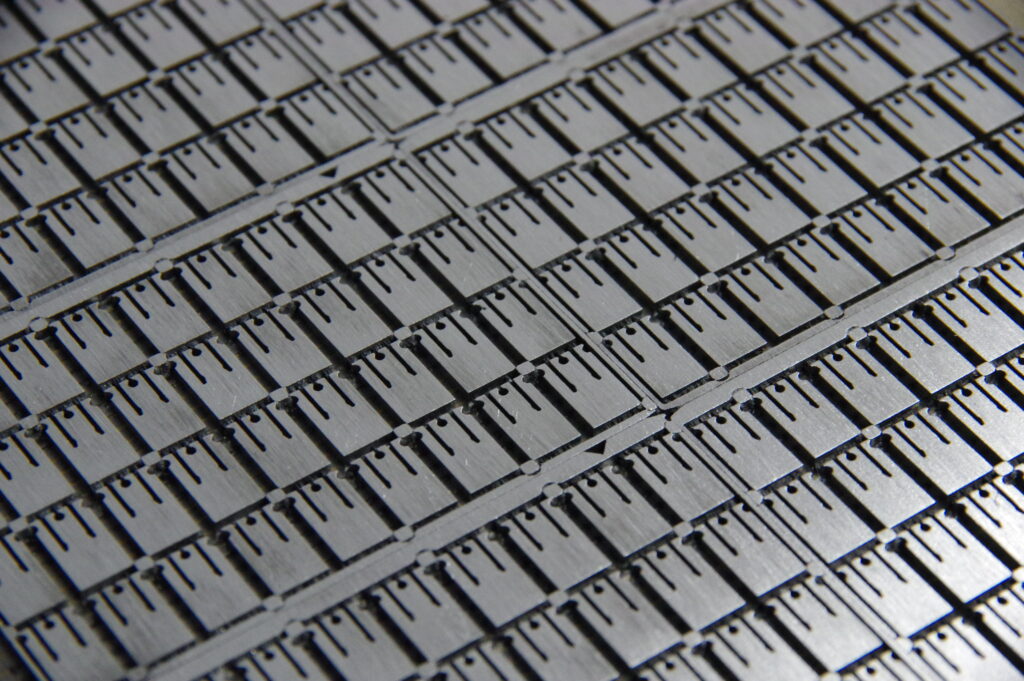

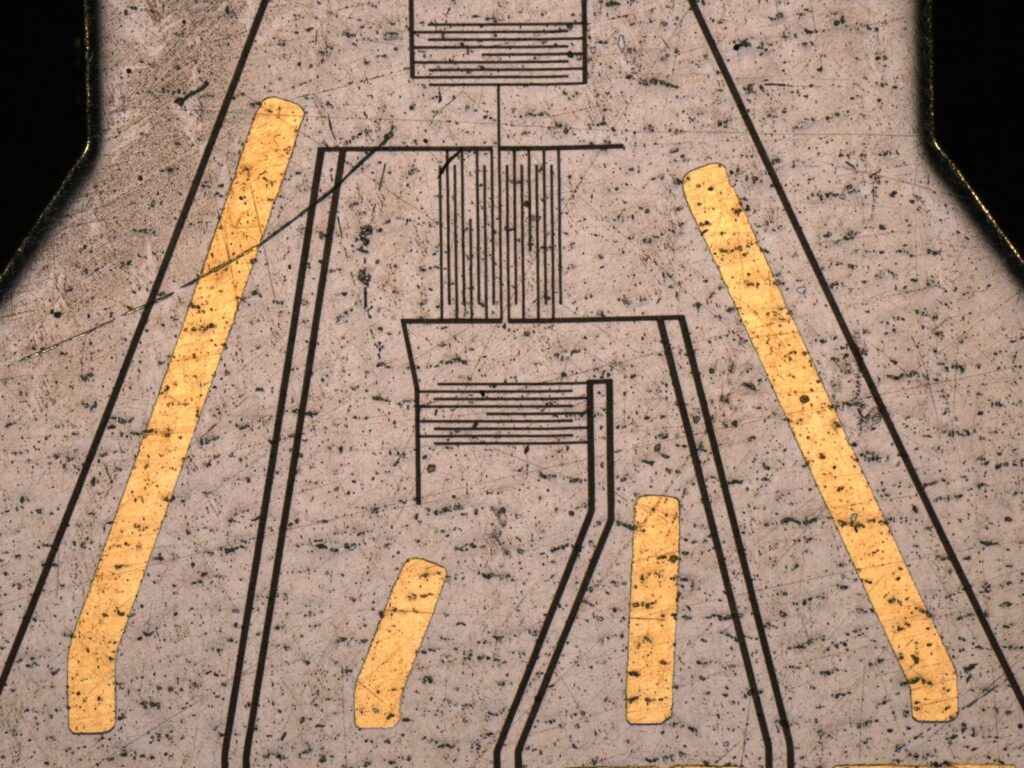

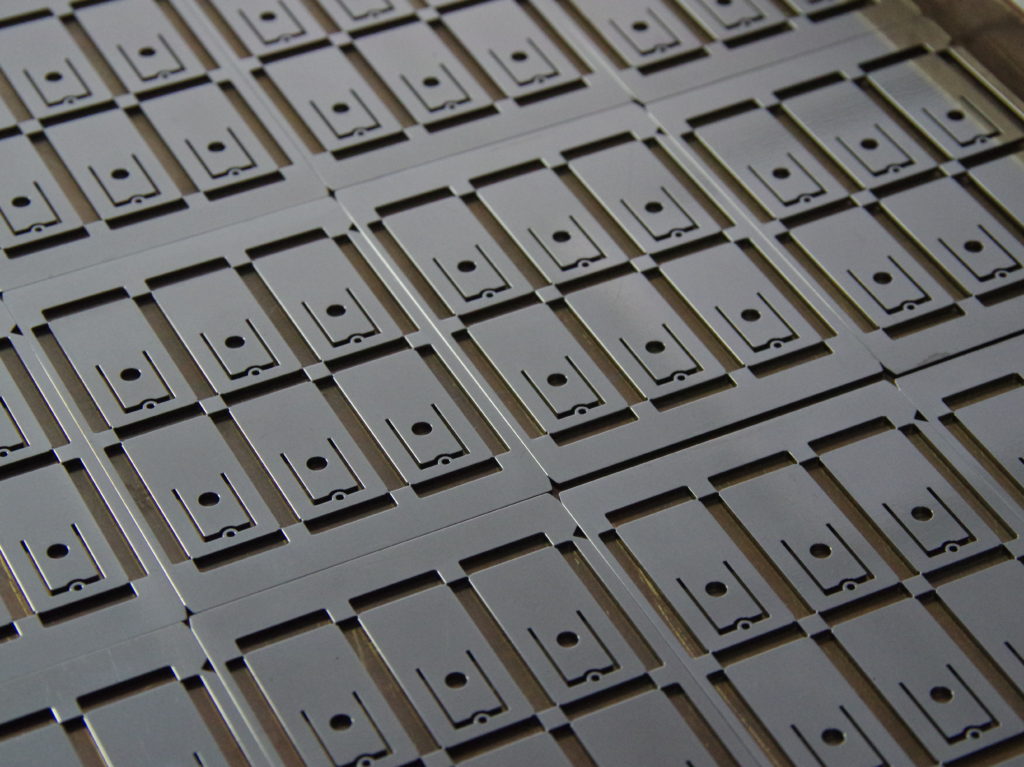

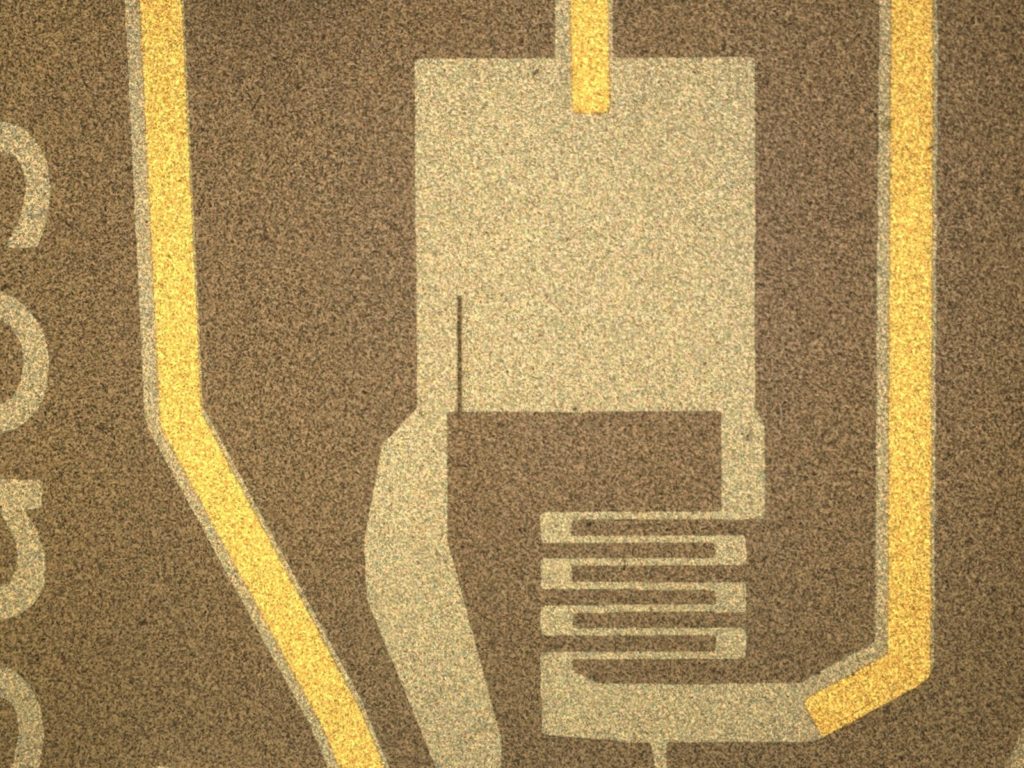

The force sensor bracket is a further development of the KB-011-0500 with a size of 9×14 mm. Initially, it is available for a force range of 20 N; however, with different sheet thicknesses, measuring ranges from approx. 3 to 100 N can be covered. The miniature sensor is mounted with an M2 screw and a dowel pin in a twist-proof manner. The force is applied to the bracket via a round-head rivet; alternatively,

two screw holes are available for usage-specific force application.

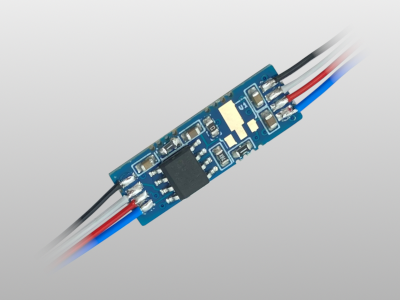

The SA-011-1500 mini signal amplifier is suitable for amplifying the output signal of a sensor directly in the supply line. This allows it to be transmitted without interference and digitized with simple means. The module is available in four variants covering operating voltages from 2.2 to 25 V and different input signal ranges. It is compatible with development platforms such as Arduino as well as with 0-10 V analog inputs.

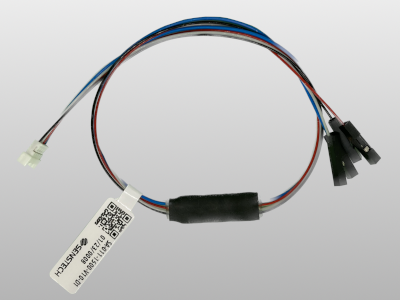

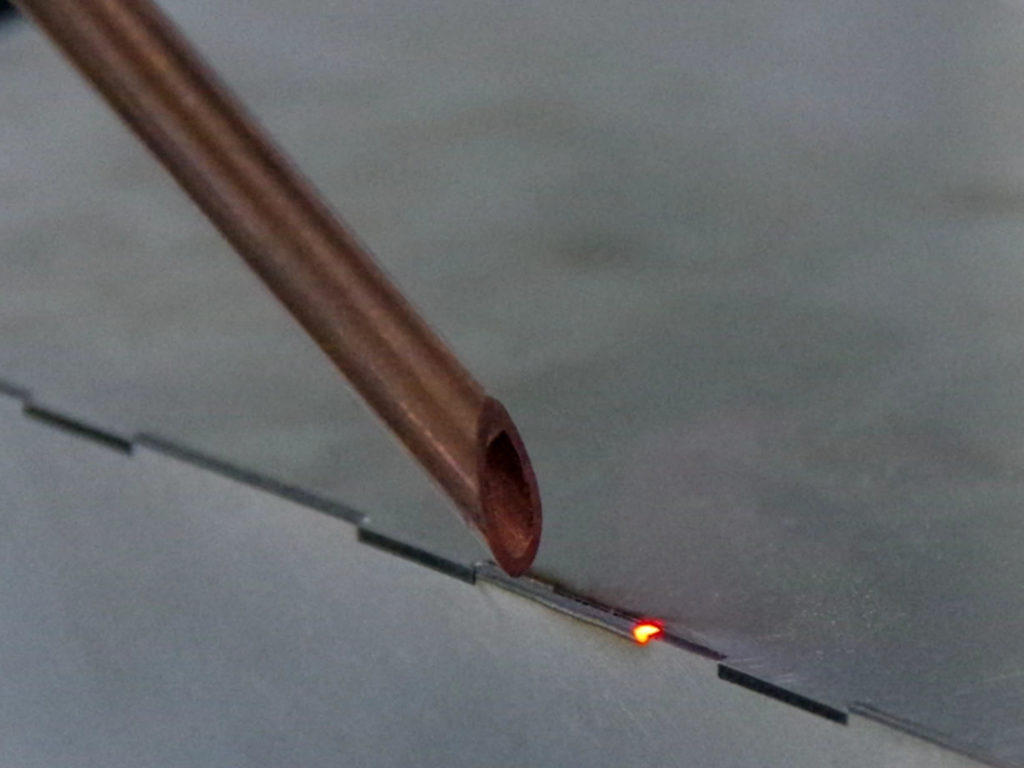

Senstech is introducing the PicoBlade connector system for all its own products with stranded wires, which enables wire-to-wire and wire-to-board connections.

This means that in future our sensors can be connected to amplifier modules or to customers' circuits without soldering.

> Mini Signal Amplifier SA-011-1500 Data Sheet

> Force Sensor Bracket KB-011-1600 Brochure