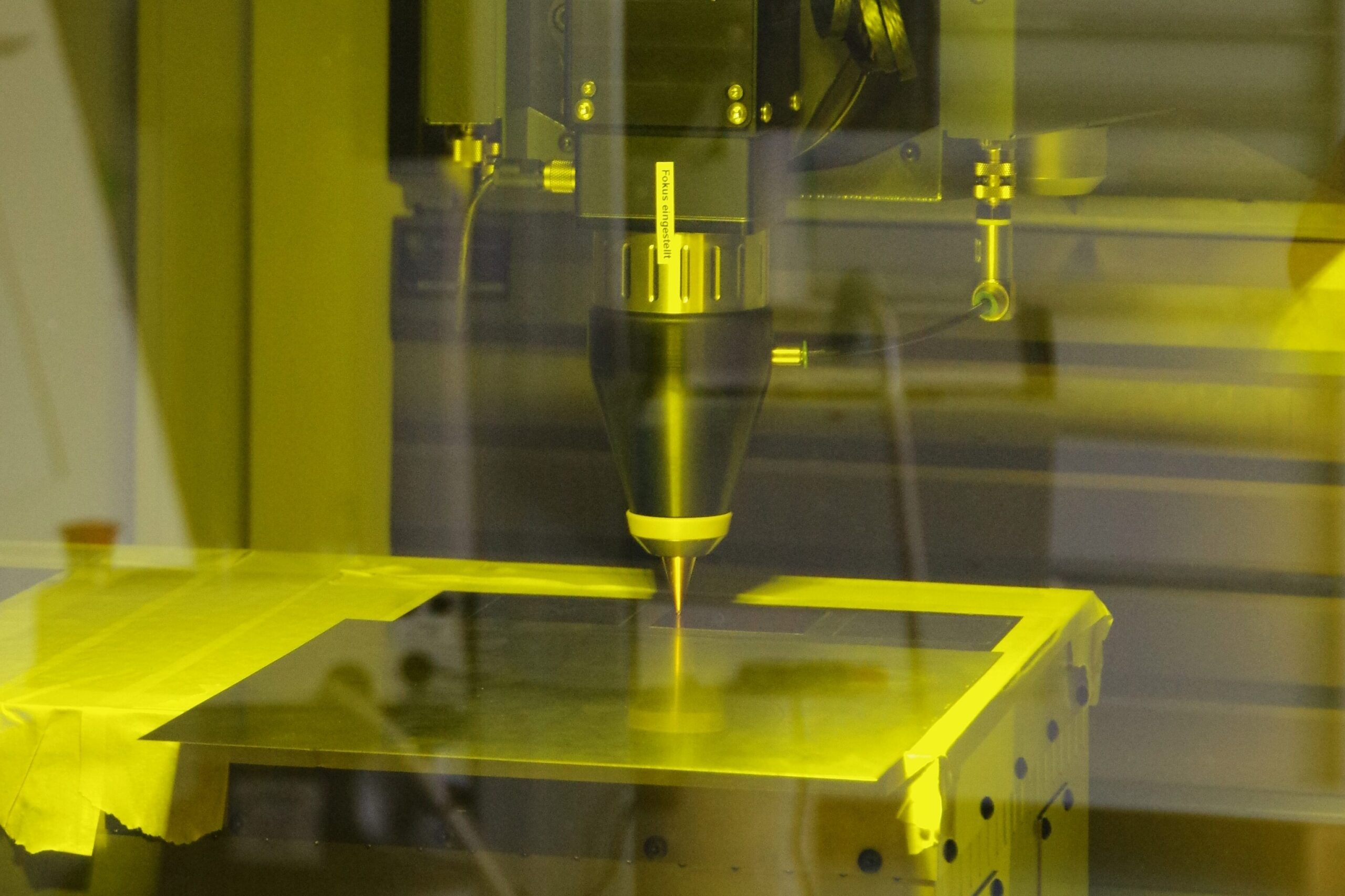

In 2020, Senstech was able to commission a second ablation laser system, which provided more reliability and capacity for structuring thin films. This year, we have now also created redundancy for the cutting laser, as we now manufacture almost all sensor substrates ourselves and have only limited fallback options in the event of a system defect. The new machining center ASKIAS Precision expands our possibilities in the production of sensor substrates and prototypes. It allows CNC controlled simultaneous 5-axis processing of parts.

Several Processing Methods in One Setup

Thanks to interchangeable processing heads, various machining processes such as laser cutting, laser drilling, laser welding, laser soldering, laser marking, laser structuring and laser ablation can be combined. It is even possible to operate two lasers in parallel within the system, such as a fiber laser for cutting and a nanosecond laser for ablation/engraving. This allows two different machining processes to be carried out on a part with a single clamping setup.

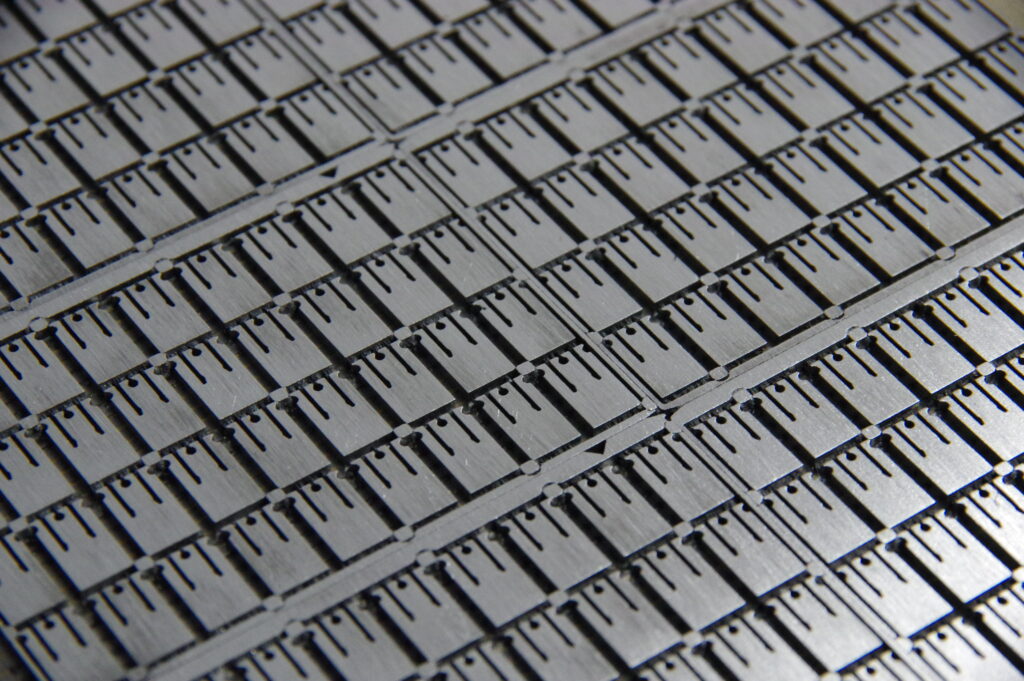

Accelerated Series Production of Sensor Panels

Due to the higher dynamics of the machine, we can produce the substrate panels for our series products about 10% faster than with our existing cutting laser.

In addition to all the process-related advantages, this investment enables us to also carry out laser welding on customer-specific parts in larger quantities, as well as to offer our own products with laser-welded housings in the future.

Excerpt of Specifications

- 2 independent zero-point clamping systems

- Axis stroke: X axis 700 mm, Y axis 400 mm, Z axis 330 mm

- Feed rate in rapid traverse: 54'000 mm/min

- Repeatability: ±0.002mm

- Fanuc B1i-B5 controller

Additional information on the Askias Precision is available in the manufacturer's video.