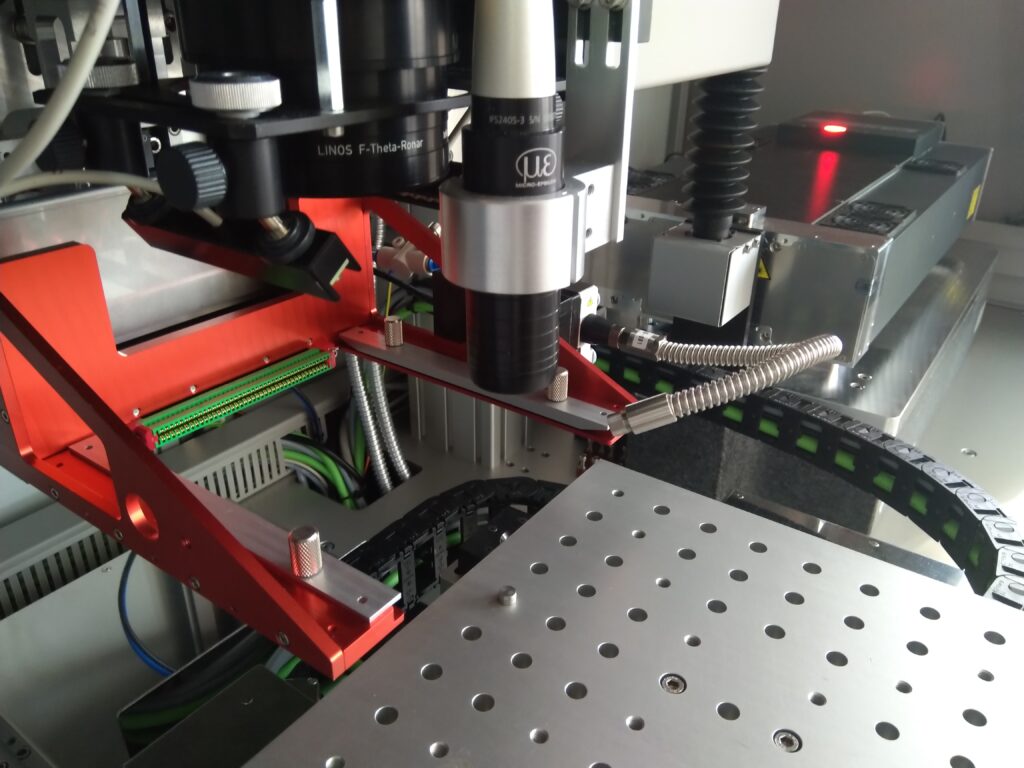

In April 2020, Senstech AG commissioned a femtosecond ablation laser from the manufacturer LS Laser Systems. The system complements the existing picosecond laser from the same manufacturer. The main purpose of the acquisition was to increase the resilience of our sensor production.

Increasing Importance of Laser Ablation

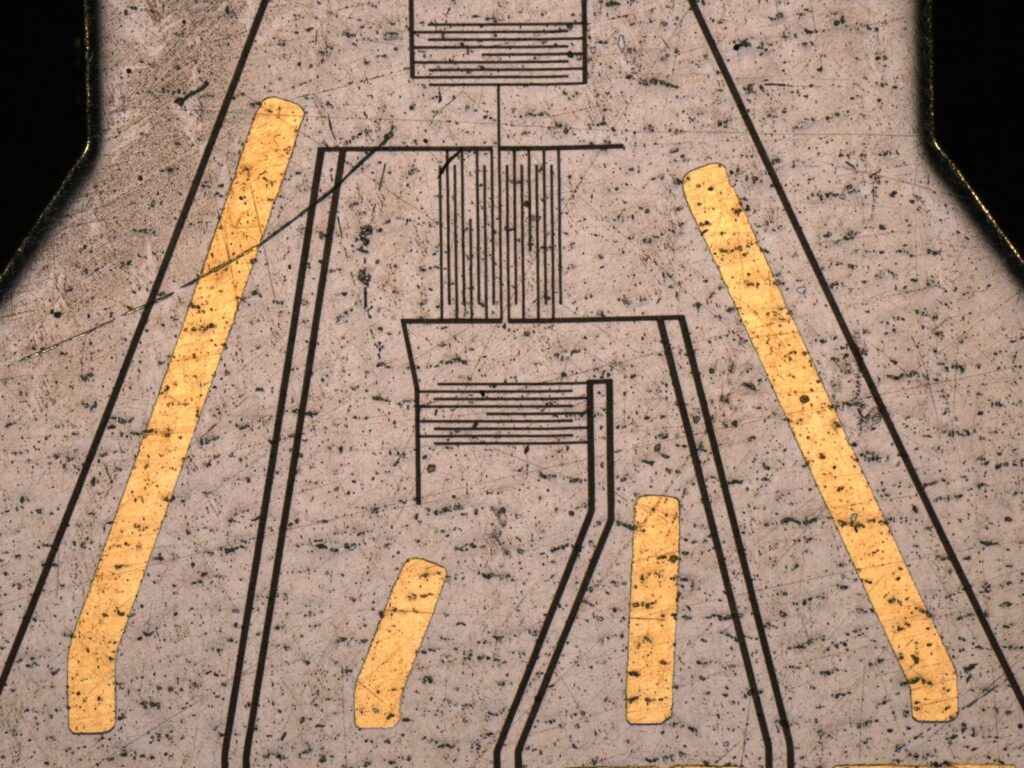

For several years, Senstech AG has been using laser technology in the production of its thin-film strain gauges. By now, almost all of our sensor elements are structured and trimmed with laser ablation. This eliminates labor-intensive photolithography processes. Instead, the thin layers are sputtered over the entire surface. Ultra-short pulse lasers are then used to cut linear structures into them, while leaving the underlying insulation layer intact. Only the gold layers used for solder pads and low-impedance tracks continue to be structured using photolithographic methods.

Securing the Ability to Deliver

For us as a component manufacturer and medical technology supplier, the ability to deliver products on time is of utmost importance, even if one of our production facilities should fail. For certain process steps, we can rely on certified third-party suppliers who perform these steps on our behalf if required. However, this is not the case for the laser ablation and trimming processes, since no company in our region has comparable equipment available. With the gradual phase-out of photolithography and the development of new sensors that require the use of laser technology, the acquisition of a second system was therefore an urgent necessity.

More Space for Process and Product Development

The increased capacity for laser ablation and trimming processes has advantages for production, but also for our development department. Additional machine time is now available that can be used for process development, such as to further optimize the productivity of ablation processes or to automate recurring measurement tasks using computer vision. It will also be easier to coordinate series production and prototype manufacturing. This creates added value for both existing and new customers.